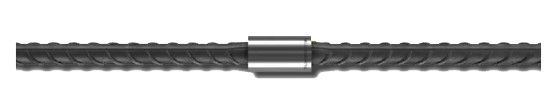

Rebar Couplers

Due to the growing technical challenges faced in the construction industry, traditional methods for rebar splicing, such as lapping or welding, are no longer the best methods.

• rebar couplers are used also for rebars splicing in reinforced concrete construction.

• rebar Couplers not only save steel, but also provide a stronger, faster and safer connection with minimum cost compared to the traditional methods.

• rebar coupler reduces material costs because less rebar is used.

• rebar coupler achieves quicker installation compared to the other splicing method, so it accelerates the schedules for reduced cost and improved efficiency.

- There are many situations where rebar couplers are more practical and cost effective than lap or welded splices:

1- large size bars are used.

2- spacing is not sufficient to permit lap splices.

3- code requirements results in very long lap splices.

4- to satisfy the maximum steel Rft. ratio of columns.

5- members may be subjected to seismic loads.

6- new rebars must be connected to the existing ones.

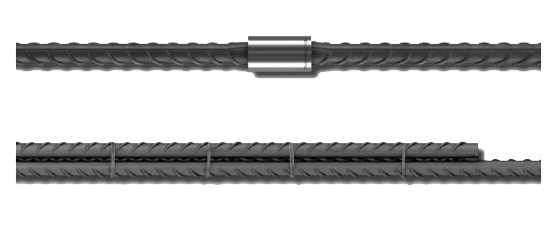

Lap Splices

Welded Splice